Linear bearings and guides

Lightweight linear motion is provided by linear guides consisting of rail and carriage. The type of linear guide affects the load, acceleration, temperature, environment and the like. It is advisable to leave the correct design of the linear guide to the design department. Linear technology products include motion screws - ensuring a rotational movement to linear as well as positioning systems combined with linear and motion screws.

Linear lines

Lightweight linear motion is provided by linear guides consisting of rail and carriage. The type of linear guide affects the load, acceleration, temperature, environment and the like. It is advisable to leave the correct design of the linear guide to the design department. Linear technology products include motion screws - ensuring a rotational movement to linear as well as positioning systems combined with linear and motion screws.

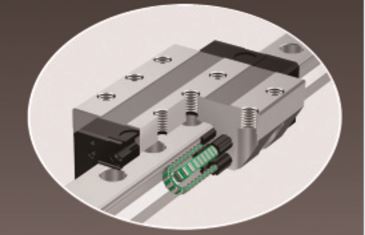

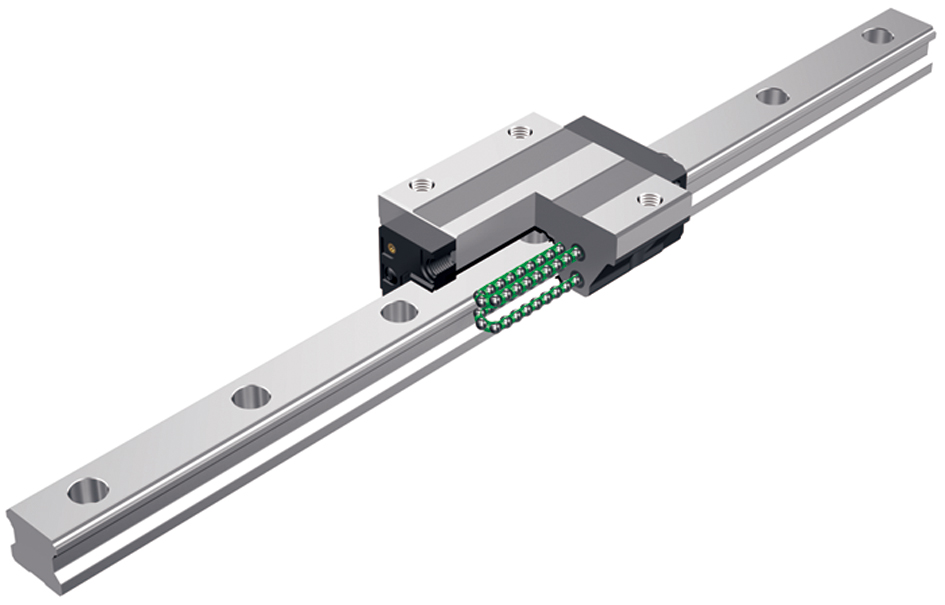

Ball Linear Guides

Low cost, reliability and precision are key parameters of linear ball guides. Their use is wide and particularly effective.

Roller linear guides

The main element of the guide is the roller, which, as with rolling bearings, means higher load capacity. Thanks to their compact design, linear linear guides can handle high loads. It is mainly used in computer controlled machines, where there is a high demand for reliability and accuracy and quality.

Miniature linear guides

Reduction of machinery, acceleration of work processes put pressure on manufacturers to reduce the build-up dimensions of components. Cooperation with reputable companies provides our company with space in this area as well.

Special linear devices

Abrasives, chemistry, temperature are the key performance parameters of each device. On the basis of customer data, in many cases special linear guides are used which have increased corrosion resistance, improved impurity removal parameters and the like. Do you have special conditions? We have solutions for you.

Motion screws

Movement bolts provide a change in rotational movement to linear motion. They are mainly used in applications where high accuracy, reliability and high acceleration are required. The termination of the motion screws can be defined by the drawing. Thanks to machinery we also provide delivery of motion screws with non-standard finishes.

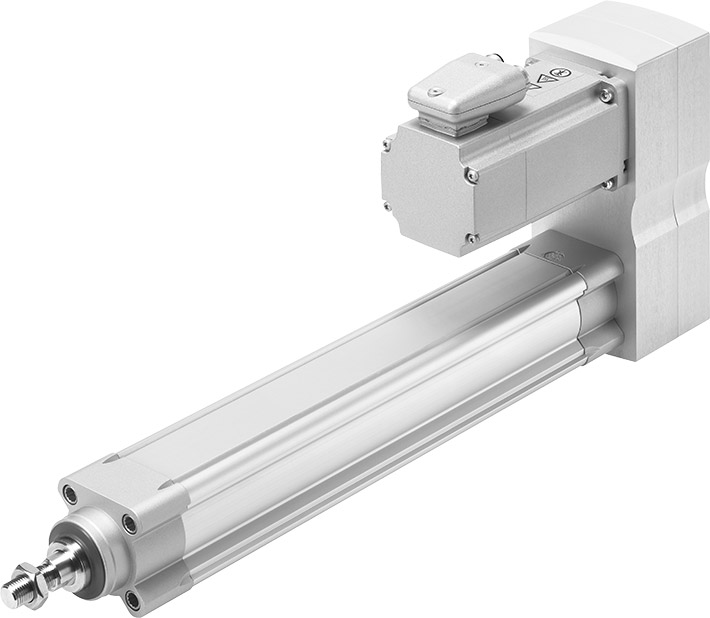

Positioning systems

The automation of production processes has also brought innovation in the handling of products during machining. The range of positioning systems depends on weight, size, accuracy, acceleration and working environment.

Catalogs Linear Bearings & Guides